Yes, the title of this entry is, of course a joke. Crop rotation doesn't mean literally rotating crops, but... well, when I came up with this I couldn't help recalling the episode of 'The Young Ones' where they get on University Challenge and Ric is taunting Neil about his swotting up whilst they're on the train to the TV studio. Swotting up on 'crop rotation in the 14th century', which, apparently, became considerably more widespread after someone called John invented a crop rotator. Back to the topic: A friend gave me this hanging chilli grower, which they found in a car boot sale, as I've been growing chillies on my windowsills for a few years now. I don't really have anywhere to hang it in my 1st floor flat, but my mum has a small greenhouse which I thought would be a better bet. Trouble is, the plants in this will only get sunlight when they're facing South(ish) and there will be at least one of them on the North side. Some means of turning it seems to me to be required here, and that's what the thing that looks like a satellite is. This is actually the Mk2 version. Mk1 used a lower reduction ratio and went around a bit faster than I'd like, plus it wasn't as neat looking.

Yes, the title of this entry is, of course a joke. Crop rotation doesn't mean literally rotating crops, but... well, when I came up with this I couldn't help recalling the episode of 'The Young Ones' where they get on University Challenge and Ric is taunting Neil about his swotting up whilst they're on the train to the TV studio. Swotting up on 'crop rotation in the 14th century', which, apparently, became considerably more widespread after someone called John invented a crop rotator. Back to the topic: A friend gave me this hanging chilli grower, which they found in a car boot sale, as I've been growing chillies on my windowsills for a few years now. I don't really have anywhere to hang it in my 1st floor flat, but my mum has a small greenhouse which I thought would be a better bet. Trouble is, the plants in this will only get sunlight when they're facing South(ish) and there will be at least one of them on the North side. Some means of turning it seems to me to be required here, and that's what the thing that looks like a satellite is. This is actually the Mk2 version. Mk1 used a lower reduction ratio and went around a bit faster than I'd like, plus it wasn't as neat looking.The two solar panels generate enough power, even on overcast days and right up to sunset on sunny days, to turn the chilli grower using a small motor and a 3-stage worm reduction gear. There's a small DC-DC converter to regulate the solar cells' output to 5V, at which voltage it draws about 25mA.

The main bearing and its aluminium cradle came out of an old water bath circulator. All the weight is supported by the bearing cradle and two steel bolts, the plastic parts don't have to carry it.

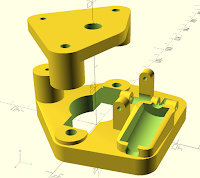

The plastic parts were designed using Open SCAD and 3d-printed. On the right here, we have the main parts, showing the cut-outs and supports for the gear train, motor and bearing cradle. The upper piece holds a second bearing to steady the main spindle. The main spindle itself was machined on a small lathe, drilled & tapped for the fixing bolt which holds a metal wire loop to hang the grower from.

Below that is a model of the geartrain, also modelled in Open SCAD. The motor cut-out and the holes for the gear shafts were generated by subtracting this from the main part above - the gear shafts were deliberately modelled longer than they needed to be to ensure that they would produce complete through-holes in the model above. The reductions are 1:52 for the motor to 1st gear shaft, followed by 1:30 and 1:60. That gives a nice easy way to measure the rotation rate - just time the intermediate gear for one revolution: however many seconds that takes, the chilli grower will complete one turn in the same number of minutes (22 with enough sunlight for the regulator to work).

Below that is a model of the geartrain, also modelled in Open SCAD. The motor cut-out and the holes for the gear shafts were generated by subtracting this from the main part above - the gear shafts were deliberately modelled longer than they needed to be to ensure that they would produce complete through-holes in the model above. The reductions are 1:52 for the motor to 1st gear shaft, followed by 1:30 and 1:60. That gives a nice easy way to measure the rotation rate - just time the intermediate gear for one revolution: however many seconds that takes, the chilli grower will complete one turn in the same number of minutes (22 with enough sunlight for the regulator to work).Here's a couple of pics of the completed crop rotator, with and without the top cover fitted.

And finally, a short video of it running. It's not quite at full speed because the greenhouse is, as you can see, in the shade of a tree at the moment.